Installation of Fire Suppression System for Electrical Panels

- May 08, 2025

- Interface Digital

Fire safety in electrical systems is not just a recommendation—it's a necessity. Electrical panels are the heart of any facility's power distribution. Unfortunately, they’re also one of the most common sources of fire. That's why installing a Fire Suppression System For Electrical Panels is essential—not only to protect valuable assets but to save lives. Let’s explore the importance, types, and installation of fire suppression systems that are specifically designed for electrical panels.

Why Fire Suppression Systems are Essential for Electrical Panels?

Before diving deep, let's clarify a common confusion – fire suppression systems and fire sprinkler systems are not the same. Sprinklers use water, while suppression systems rely on clean agents or gas to minimize electrical damage.To understand the difference in detail, refer to our blog - Fire Suppression vs Fire Sprinkler: Key Differences you must know!

Importance of Having a Fire Suppression System For Electrical Panels

Electrical panels, which are critical for distributing energy, can cause fires owing to their high quantities of components and wiring. Rapid fires result in significant damage, downtime, and are a safety hazard. Fire suppression systems built for electrical panels can reduce these risks by identifying and extinguishing flames at their source. It avoids escalation, reduces damage, protects key infrastructure, minimizes business disruptions, and ensures safety rules are followed.Common Causes of Electrical Panel Fires

Electrical fires often start with many things such as:- Overheating

- Short circuits

- Loose connections

- Overloaded circuits

- Faulty equipment

Components of Fire Suppression Systems

1. Detection Mechanisms

These systems use a variety of detection mechanisms, such as heat sensors, smoke detectors, and gas sensors, to detect indicators of fire or overheating in the electrical panel.2. Control panel

It serves as the brain of the fire suppression system, analyzing data from detecting sensors and activating the suppression mechanism as needed. It enables change of settings as well as remote monitoring and control.3. Suppression Agents

Suppression agents such as inert gases, dry chemicals and foams are used to suppress rapid fires. These agents are dispatched to extinguish the fire promptly and effectively while minimizing future damage to electrical equipment.4. Distribution system

It consists of pipe or tubing that is linked to the suppression agent storage container, as well as strategically positioned nozzles or outlets within the electrical panel. It ensures equal diffusion of the suppression agent, resulting in complete coverage.5. Activation Mechanism

Once the system detects fire, the activation mechanism in the system discharges the suppression agent into the electrical panel. This can be initiated either mechanically by the control panel or manually by an operator.Best Fire Suppression System for Protecting Electrical Equipment

Many types of fire suppression systems are commonly employed for electrical panels:1. Clean Agent Fire Suppression Systems

Clean Agent Systems: Systems with Inert gases that include FM-200, CO2, or Novec 1230 are preferred to extinguish fire. It reduces oxygen levels and interferes with any chemical reactions. Clean agent systems are great for preserving sensitive electronic equipment since they leave no residue and are completely safe for people.2. CO₂ Fire Suppression Systems

Carbon dioxide or co2 fire suppression system for electrical panels successfully extinguish flames by smothering them, inhibiting oxygen combustion, and being non-conductive, making them safe for electrical fires. However, chemicals employed in these systems may create problems, so inspect the contents before the purchase.3. Inert Gas Systems

Inert gas systems, such as those using IG-55 or IG-541, suppress fires by lowering the oxygen concentration inside the electrical panel to a level where combustion cannot be sustained—but still safe for humans in surrounding areas. These gases are non-conductive and residue-free, making them ideal for sensitive electrical environments.Note: While inert gases are used in larger enclosures or server rooms, for compact control panels, direct-release systems like Novec 1230 or FM-200 are more commonly employed due to faster activation and better space utilization.

4. Dry Chemical Systems

To smother flames, use dry chemical agents such as ABC powder or potassium bicarbonate, which block the combustion process. While these methods are efficient, they can result in residue that must be cleaned up and can be harmful to some materials.5. Aerosol-Based Fire Suppression Systems

These systems use a solid chemical compound extinguishing agent that degrades and releases when the system is triggered. When triggered, the extinguishing agent interrupts the fire's chemical chain reaction by eliminating oxidants from the burning process.6. Electrical cabinet fire suppression system

An electrical cabinet fire suppression system is intended to swiftly detect and extinguish flames within electrical enclosures, therefore avoiding damage and delay.How Fire Suppression Systems Work?

These systems detect, respond to, and suppress fires within control panels using a combination of heat detection tubes, suppression agents, and quick discharge valves.Key Components:

- Detection Tube: A flexible, pressurized tube installed inside the panel that bursts upon exposure to high heat, triggering suppression.

- Discharge Valve: Releases the extinguishing agent immediately when the tube ruptures.

- Suppression Agent: Typically includes Novec 1230, FM-200, or Inert Gases such as IG-55 or IG-541.

- Alarm Module (optional): Alerts nearby personnel or connects to central fire systems.

1. Detection Mechanism

As we spoke in components, these systems detect fires using smoke or heat sensors and linear heat-sensing cables that run through the panel. They are sensitive and can catch overheating before it becomes a flame.2. Suppression Activation

If it is triggered, the system releases the suppression agent—automatically and almost instantly. The goal is to eliminate the fire before it grows or spreads. To know more about suppression agents, check out the components section above.3. System Reset and Recharging

Most modern electrical panel fire suppression systems are designed for ease of reset and recharging.- Direct-release systems: The detection tube and suppression agent are replaced or refilled.

- Pre-action systems: Control units and valves can typically be reset with minimal manual effort.

Key Features to Look for in a Fire Suppression System

1. Pre-Action Systems

Pre-action systems are intended for areas prone to considerable damage or disruption. It needs confirmation of fire detection to avoid false alarms and provide dependable protection against unintentional discharges.2. Early Warning Systems

Some fire suppression systems employ modern sensors, infrared imaging, or machine learning algorithms to offer early warnings of possible fire dangers, allowing people to take preventative steps and lower the risk of fires.3. Remote Monitoring and Control

Modern sprinkler systems provide remote monitoring and control capabilities, allowing site managers to monitor system status, respond to possible fire occurrences, and improve operational efficiency and safety.4. Integration with Existing Safety Systems

BMS integration improves fire suppression by centralizing control and monitoring, allowing for automated responses and increasing safety and efficiency.Installation Guidelines and Best Practices

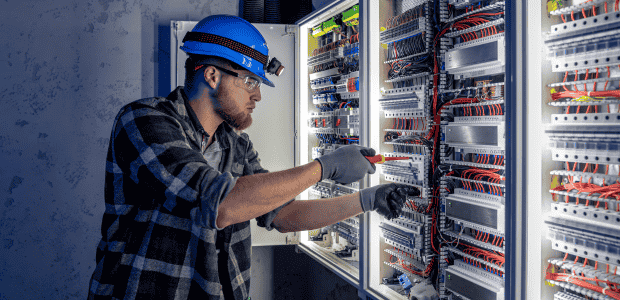

One must know the guidelines and how to use these systems thoroughly. If you are installing DIY then the below points must not be ignored:1. Site Assessment and Risk Analysis

Start with a professional risk assessment. Identify hotspots, load capacities, and vulnerabilities in the panel. This ensures the solution is custom-fit to your environment.2. Panel-Specific Design Considerations

Different panels require different setups. Size, airflow, and equipment sensitivity must all be considered in the design phase.3. Maintenance and Inspection Requirements

Routine checks ensure the system is operational. Many regulations require annual inspections and periodic recharging.4. Regulatory Compliance

Authorities like NFPA (National Fire Protection Association) and IEC (International Electrotechnical Commission) require certain businesses to have advanced fire safety solutions.5. Cost Considerations

The starting cost of installing a fire alarm system is covered by its ability to prevent significant incidents. Pricing is negotiated based on:- Panel size

- Agent

- Installation complexity

- Certification requirements

Which Places Is Fire Suppression System Used The Most?

An automatic fire suppression system for electrical panels can be installed in many places such as:1. Data Centers and Server Rooms

High-value electronics and zero tolerance for downtime make these areas prime candidates for clean agent systems.2. Manufacturing and Industrial Facilities

Machinery and control panels are fire risks due to high power loads—making suppression systems a necessity.3. Commercial Buildings

From retail centers to office buildings, protecting electrical distribution panels is critical to run a business.4. Energy and Utility Sectors

Power plants and substations depend on uninterrupted operations. Fire in a panel here could lead to a grid-wide failure.Why choose Interface Digital for installing a Fire Suppression System for electrical panels?

At Interface Digital, we prioritize fire safety by providing dependable fire suppression solutions, such as integrated pre-action systems and foam systems, to safeguard your home and loved ones. Below we have mentioned the benefits of installing our fire suppression systems:- Early detection: Our technologies help detect fires early on, allowing for prompt action to prevent them from spreading.

- Instant fire detection: Our fire suppression system catches fires instantly. It enables rapid evacuation, saving lives and precious assets.

- Reduction in Property damage: These systems dramatically decrease property damage, resulting in cost savings for both assets and workers.

- Eco-friendly: Our unique solutions, like Novec gas, are environmentally safe, posing no risk to the ecosystem or sensitive equipment.

- Reliable: These systems provide continuous protection, ensuring building safety even when no active threats are present.

- Customizable: At Interface Digital, we customize solutions for specific sites and fire dangers.

Frequently Asked Questions (FAQ)

Q1. What is the Firetrace system for electrical panels?

The Electrical Panel Fire Suppression System uses a patented continuous linear sensor tube. It precisely detects fires and activates extinguishing agents using pneumatic technology.Q2. How does the Firetrace system work for panels?

The Firetrace system uses a heat-sensitive detection tube routed through the electrical panel. When exposed to high heat from a fire, the tube bursts at the hottest point, releasing a clean agent like Novec 1230 directly onto the flames. It works automatically and without the need for external power.Q3. What is Novec 1230, and why is it used?

Novec 1230 is a clean, non-conductive, and eco-friendly fire suppression agent that leaves no residue. It’s ideal for electrical panels because it quickly extinguishes fires without damaging sensitive components.Q4. What are inert gas systems, and are they used for panels?

Inert gas systems use gases like nitrogen and argon to reduce oxygen levels and suffocate fires. While they're more common in server rooms and large enclosures, some industrial-grade panels may use them depending on the application.Q5. Can the system activate without a fire?

False activation is extremely rare due to the pressure-sensitive nature of the detection tube. The system is designed to trigger only at high temperatures, ensuring reliability.Q6. What makes Interface Digital a reliable choice for this system?

Interface Digital offers certified installations, industry-grade materials, and fast service support. We also provide AMC and system health checks, making us a dependable partner for long-term safety.Conclusion

Electrical fires do not knock before entering; they spark, ignite, and destroy in seconds. Installing a reliable fire suppression system for your electrical panels isn't just a safety requirement—it’s smart risk management. These systems act fast, cause no secondary damage, and prevent full-blown electrical disasters. Whether you manage a data center, or a factory, investing in the right system today might save you from costly consequences later on.With Interface Digital, you're choosing industry-backed expertise, certified installation, and ongoing support—protecting your assets from within. Contact us to schedule a site evaluation and get a customized fire suppression solution for your electrical panels.